It’s time to make some ordinary into extraordinary. Are you measuring the weights and the dimensions from the human hands? Well, not anymore!!

Pallet Dimensioner helps to speed up the process and improve the efficiency of the warehouse. However, depending on the manual processes might always be frustrating, and the lack of automated systems in your warehouse will lower your productivity. In addition, human processes will make an error in producing the correct measurements. As an outcome, there will be a poor outcome for the product, poor efficiency and heavy expenses.

What’s that Pallet Dimensioner? And why do you need that?

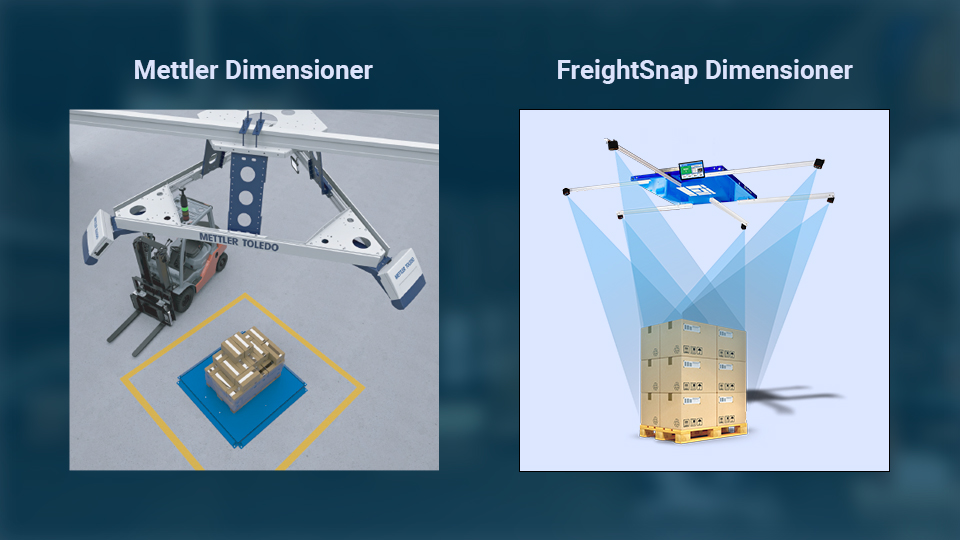

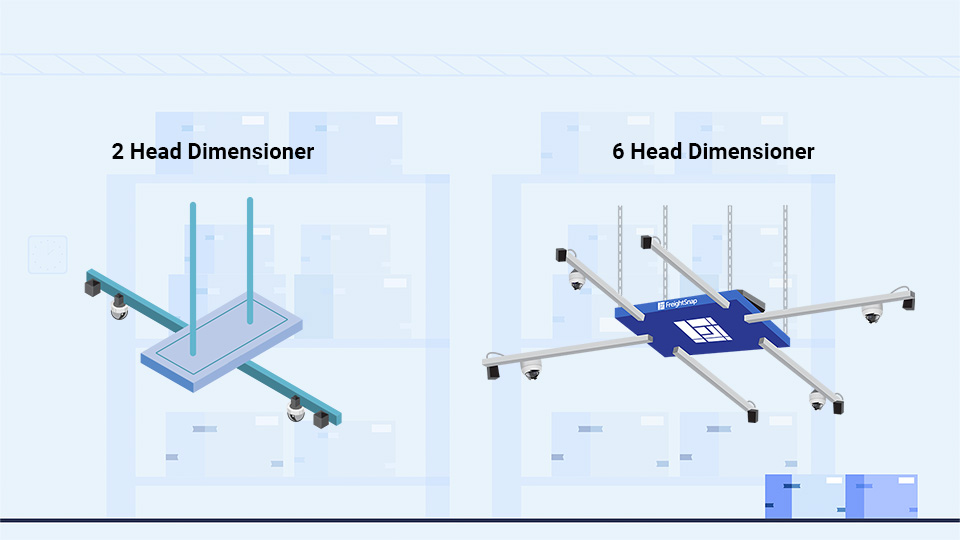

They are the wanted technology in which warehouses need to automate pallet dimensioning to capture length, width, height and weight. It consists of a 3D sensor dimensioning technology with high-definition cameras specially designed to quickly and accurately measure unshaped load.

But on the other dimension, the manual process consists of measuring pallets with tape to calculate weight, taking pictures, and uploading the data into the system because the manual procedures are always time-consuming and tend to get human errors.

A pallet dimensioner is a valuable and necessary investment for warehouses.

Let’s scroll down and see the 7 benefits of using a pallet dimensioner!!

Improvement In Your Warehouse Productivity

Imagine manually capturing pictures and measuring the dimensions and weight of each pallet. Looks like forever, right?

Higher Accuracy

Warehouse operations depend entirely on an error-free environment to avoid inaccuracies that can come at a high cost. Therefore, investing in an automated pallet dimensioner can help warehouses reduce measuring inaccuracy and manual errors is essential.

A pallet dimensioner uses laser and 3D-based dimension technology with perfect-quality cameras and digital scanners. They are well-equipped with modern technologies to measure every pallet’s precise dimensions accurately.

Enhances Revenue Growth

Capturing pictures and measuring dimensions and weight for the pallets would be tiresome, resulting in backwards due to the manual process. So it will be challenging to understand how to charge customers properly without accurate data. Imagine what if you are charging less to your customer? Well, it’s your loss of money. Also, what if you overcharged them? It’s time to say goodbye to your loyal customer.

Automating the pallets measuring process will boost the efficiency of the warehouse by increasing its capacity for processing rather than manually measuring it, which results in higher productivity and revenue growth.

By measuring the process automatically, the dimensions will always result in accurate measurements. As a result, the visibility of cost-cutting will be higher, which boosts revenue and customer satisfaction.

Significant Growth In Profit

Let’s assume that your productivity improved and saw visibility in gaining maximum profit!!

It is possible to attain that goal if your warehouse has an automated pallet dimensioner. They are very cost-efficient and reduce the time compared to measuring it manually. It needs less time to analyze the value to earn profits by cutting labor costs.

Availability Of Proper Space

The spaces are good, like always good. Warehouses would always run out of space because of their wholesome needs. Without space, it is impossible to run the warehouse.

Installing the pallet dimensioner will be an excellent option for using the maximum warehouse space. It effectively increases the storage capacity by measuring the dimensions and weights and capturing the images more accurately.

Proof Claimer

Your package returned with the claims from the customers’ side; what will be the ultimate goal of claiming it?

Having proof is way more than enough to deal with the customer’s claims. With the help of a pallet dimensioner, the captured images will be the saver of the day. In addition, the living proof from your side will be ideal when a pallet is shipped or received out of the warehouse.

It is necessary to have proof if the product went out of the warehouse in customers’ hands to check whether it’s in perfect condition.

Certified Measurements

The regulatory bodies assess pallet dimensioners based on precision and maximum and minimum measurement size. Therefore, before purchasing an automated pallet dimensioner, study for the qualification marks to see whether the dimensioner is approved.

Closure Thoughts

Opting for a pallet dimensioner for your warehouse will always succeed in going in the right direction. However, it lowers the time and benefits of providing your warehouse with the desired results or outcome.

In the end, your improved processing speed, accuracy, and efficiency will be visible. Furthermore, having these benefits will help warehouses cut labour costs, utilize space better, enhance revenue, and more.