We tested them, here is what we found.

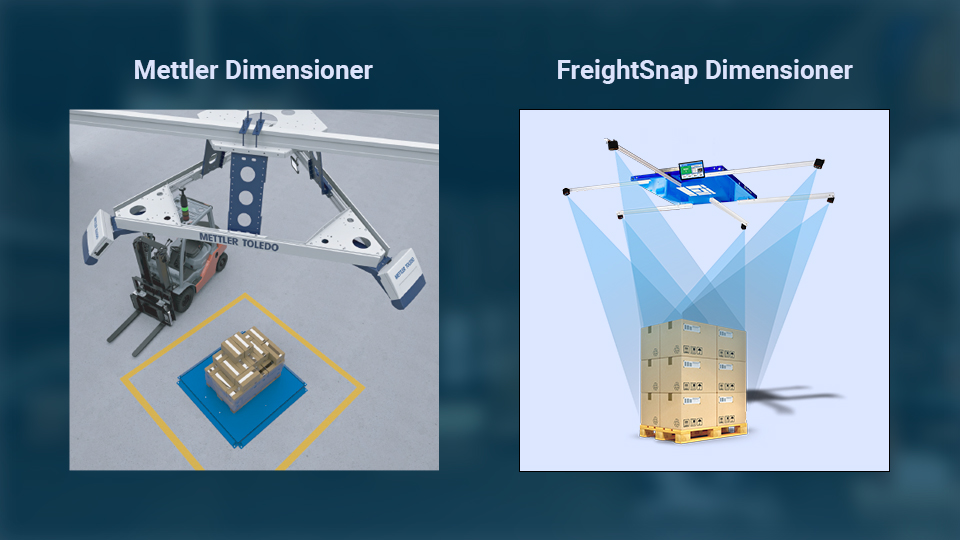

Manufacturers are always pushing the envelope to come up with cost effective solutions to compete against the established names in the industry. Pallet Dimensioning is no different. The established brands from Mettler, FreightSnap, Cubiscan, and Rice Lake all provide tried and true products utilizing various technologies from Lidar to Infrared.

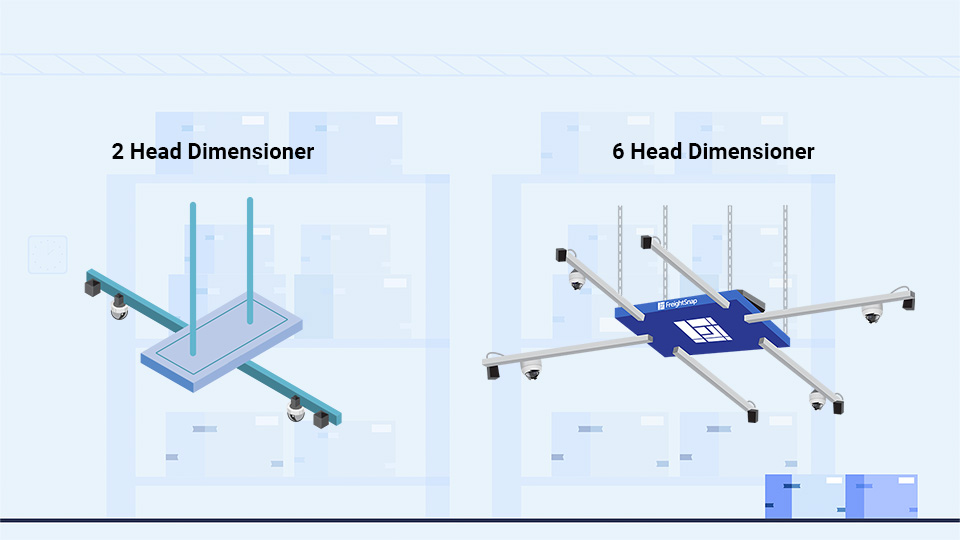

Now we are seeing less expensive solutions from companies like BeeVision and Cargo Spectre enter the marketplace using 2 headed infrared or structured light solutions. We were fortunate enough to get our hands on the Cargo Spectre solution and compared it with another infrared solution from FreightSnap. Right off the bat you can see the difference between the two solutions. The FreightSnap FS 5000 had 6 sensors which surrounded a huge measurement area of 168” x 120”, which allowed for the measurement of just about anything you wanted. The Cargo Spectre Dimensioner was set up and the two headed solution spanned about 8 feet diagonally over the top of a scale.

The Testing

We first used a 40×48 pallet with some freight in the center of the pallet and both units were able to measure this without issue.

In the second test, we positioned a box to hang over the edge of the pallet so that is measured 52″ x 40″ and 72″ tall. On the first test, the Cargo Spectre Unit measured it at 51” x 40” x 72”. The FreightSnap unit measured 52.5 x 40 x 72. So, both were close, but it seemed the FreightSnap unit was within the ½” tolerance.

The third test we conducted was to actually take the same piece of freight from the 2nd test and rotate it so that it was diagonal at around 45 degrees to the placement of the second test, which was somewhat squared off to the measurement zone. This is where the units really started to diverge. The Cargo Spectre unit measured 40.5 x 48.5 x 72. The FreightSnap unit measured 52 x 40 x 72. During this test, we continued to rotate the pallet and check measurements.. The FreightSnap unit stayed within tolerance, but the Cargo Spectre unit did not. It continued to provide a different measurement on every rotation. It would only remain in tolerance when the pallet was square.

The 4th test we performed was one where we placed a long pallet in the zone and rotated it like the hands on a clock. On one end of the pallet was a set of boxes that were 96″ tall. See the image below.

Boxes are placed on one end of the pallet up to 96” tall. We rotate it around like the hands on a clock to see if the unit can get the correct measurements. The actual size of the pallet was 96” x 48” x 96” tall. The two units could not have performed more differently. The Cargo Spectre unit could not see the top of the boxes when they were rotated away from the sensors. Out of the 8 scans taken, they were only in tolerance on two occasions and wildly out of tolerance on 6 scans. The FreightSnap unit stayed in tolerance on all 8 scans. It was obvious that having 6 sensors surrounding the zone made a huge difference in the capabilities of the units.

The Last Test – We wrapped a 48”x60”x48” pallet with black shrink-wrap material and did the same rotation test. Out of 7 tests, the Cargo Spectre was only able to be in compliance on one of them. On the other 7 placements, they were all wildly out of compliance and produced inconsistent measurements. The FreightSnap unit was in compliance on 7 scans and slightly out of compliance on 1 scan with Black Shrink-wrap.

Testing Conclusion

The Cargo Spectre unit would be useful in some applications. Basically, in those situations where the users knew and understood that the freight needed to be presented in a certain way to achieve an accurate result. They would also need to know that color is an issue. The FreightSnap unit passed all of the measurement tests without issue. The traditional dimensioner performed better than the two headed unit from Cargo Spectre..

NTEP Testing

It was disappointing to see that NTEP had tested both of these units but was not able to properly ascertain the limitations of the two sensor unit. In talking to industry experts, this has been an issue that Manufacturers of premium equipment have complained about under their breath for the last couple of years as some of these less expensive products have come on the market. Some of the explanations I was given is tied to the way the Handbook 44 (The Official Guide) for testing has been put together and that the requirements in the United States are much different than those in Europe and Canada. Which makes sense as Dimensioning in a rather new process in the United States vs Europe and Canada. All of the top tier units from Cubiscan, Mettler Toledo, Rice Lake, and FreightSnap have all been certified around the world where the standards are much tougher. None of these less expensive solutions that have made their way onto the U.S. market have been able to achieve certification in Europe or Canada.

Value

This was something that blew me away. Cargo Spectre advertises itself as being the least cost alternative on the market. I did not find that to be the case. In a presentation that was forwarded to me by the company they had presented it to, the costs for the Cargo Spectre were as follows.

Initial Set up fee of $4,500 plus installation and a monthly cost of $600 per month. I reached out to a few vendors to obtain a quote that would be apples to apples. This surprised me. I received a few quotes back from vendors that offered a setup fee and month to month pricing, and the FreightSnap quote was interesting. They offered a $7,500 Setup fee, which included installation, and $395 per month, with a lifetime warranty on the components for as long as you kept the system. By all measures, the superior device was actually less money over the long-term. Cargo Spectre did not have a direct purchase option for the unit. FreightSnap does offer outright purchases of their equipment with support programs.

In conclusion, I would stay with a traditional dimensioner from the big 4 brands of Cubiscan, Mettler Toledo, Rice Lake and FreightSnap. In measurement tests we performed on all of the traditional units, they all performed well. The biggest difference with the big 4 is price. As discussed in previous articles, some of the older traditional machines utilize expensive Lidar devices which add substantially to the cost. FreightSnap appears to offer the best Month to Month option of all units traditional and non-traditional units investigated.