Pallet dimensioners, also known as “cubing systems” or simply “dimensioners,” are used by shippers to automate the pallet measurement and documentation process – a process which until recently has consisted of measuring freight with a tape measure, taking a photo of the freight with a digital camera or phone, and then transferring that information to a WMS or TMS system by hand. Dimensioners do all of that for you in just a few seconds, making them a valuable and even necessary investment for high-volume shippers.

With that in mind, we’re looking at some of the major characteristics that define these products, and outlining the features you should pay attention to before deciding which pallet dimensioner to buy.

Measurement Range

Dimensioning companies list the measurement capabilities of their units in terms of length, width and height. On the market today, you can find pallet dimensioners that can measure anywhere from 72” x 72” x 96” on the low end, all the way up to 132” x 96” x 108” on the high end. Some companies like FreightSnap even offer custom pallet dimensioners capable of measuring even larger items.

Understandably, units capable of dimensioning the largest freight tend to be more expensive, which is why it’s smart to figure out which dimensioner is going to be able to accommodate most, if not all of the freight sizes you ship. To do this, we suggest looking back at the freight you’ve shipped over the last six to eight months. From there, you can create a size profile that accounts for at least 90% of the freight you regularly ship.

To get the most out of your investment, the pallet dimensioner you choose should be able to measure anywhere from 90% to 100% of the freight you ship.

Measurement Accuracy

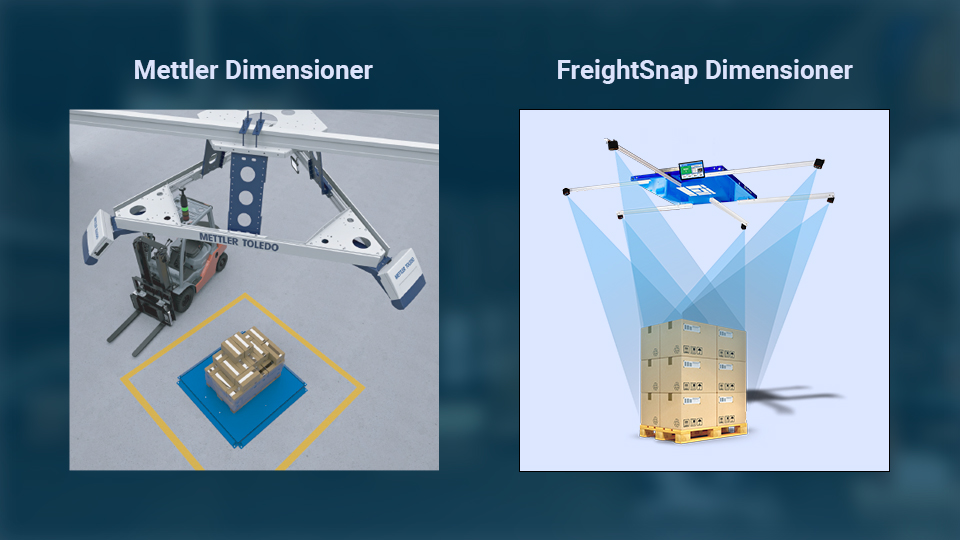

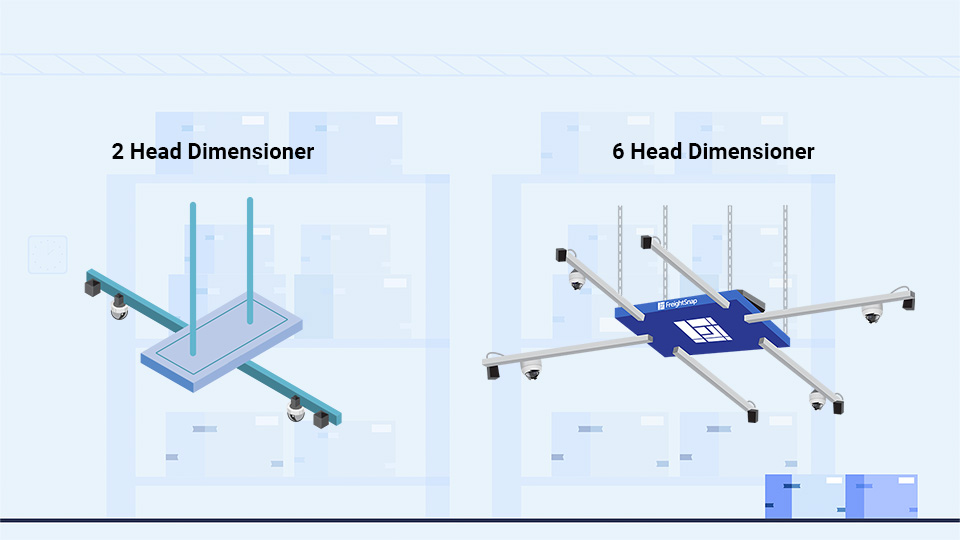

The measurement accuracy of dimensioners is determined in large part by the kind of dimensioning technology being used. Most pallet dimensioners use laser-based technologies or 3D infrared technologies. You can read more about the differences and benefits of these technologies here.

Traditionally, laser-based dimensioning technologies have been more accurate than infrared options, however, in recent years, infrared dimensioners have closed the accuracy gap. Before buying, you’ll want to make sure the dimensioner you choose has an NTEP- certified accuracy of at least ±0.50”.

Freight Documentation

In addition to measuring, some pallet dimensioners will also take a photo or photos of your freight to document its condition before shipping. This documentation is useful in a couple of ways. For example, the photo can be sent to a carrier, which helps them plan the best way to stow your freight on a trailer to maximize space and ensure that your pallet doesn’t get damaged in transit.

If your freight does get damaged on the way to its destination, the photo(s) can also be used as evidence in a damage claim, which can increase the probability of reimbursement.

Equipment & Process Integration

Let’s say you want to capture the weight of your freight at the same time you capture dimensions. In that case, you’ll want to integrate your dimensioner with a floor or forklift scale. Maybe you want to trigger your dimensioner by scanning a barcode tied to each pallet. For that, you’ll need to integrate a barcode scanner. Some dimensioners can even be installed above pallet wrappers, giving you the ability to wrap and then measure your freight all in one step.

Before you buy, check to make sure the pallet dimensioner you’re considering can be customized to your process. A dimensioner should make your life less complicated, not more so.

Measuring Speed

Also referred to as “scanning speed” or “scan time,” measuring speed is the time it takes for a pallet dimensioner to measure a piece of freight after the dimensioner has been triggered. Most fully-automated pallet cubing systems take between 3 and 6 seconds to scan one pallet, which is much less than the 30 or so seconds it takes to measure a pallet by hand.

Software Integration

To get the most out of your pallet dimensioner, you may want to integrate it with a WMS, TMS or ERP system. Doing so can help you eliminate data entry errors and make better use of the dimensional data collected.

Alternatively, most dimensioners can also work as standalone solutions, offering an interface where you can trigger the dimensioner and view the measurements captured in real time. One pallet dimensioner even offers a cloud-based interface and repository where users can look up information on individual shipments and generate analytical reports based on all the dimensional data they’ve collected over time.

Certification

Different countries have different certifying agencies. In the United States, The National Conference of Weights and Measures (NTEP), is responsible for testing and awarding certifications. In Canada, Measurement Canada serves this function. OIML, another major certification organization, has 61 member states, which includes various countries in Europe, South America, the Middle East, Africa, Asia, and Australia.

Each of these regulatory bodies evaluates pallet dimensioners in key areas like measurement accuracy, maximum measurement size, minimum measurement size, and safe operating temperature. Before buying, look for the certification marks (pictured below) to see if the dimensioner you’re considering is certified. You can also search the NTEP certificate of conformance database, Measurement Canada database, or OIML website to find out if the dimensioner you’re looking at has earned certification in your country.

And remember, many LTL carriers are already using NTEP-certified pallet dimensioners to bill or re-bill their clients. The only way to dispute these re-bills or negotiate more favorable shipping rates is with NTEP-certified measurements of your own.

Customer Support

Capital equipment is expensive, which is why you always want to buy from a company that stands behind their products. Consider the warranties offered by manufactures – some will inevitably be better than others.

Also pay special attention to maintenance. How does the manufacturer handle service calls? Do they guarantee a fast response? Do they charge fees for every little issue, or is most service included in your purchase price?

The company’s reputation in the industry is also important. Talk to other businesses who’ve used their products and look for customer reviews online. You may even send a message to some of the business’ current clients. Most companies are happy to offer their opinion of a product or service they’ve invested substantial capital into.

Cost & Scalability

Price should always be a major factor in your consideration process. Although many of the top pallet dimensioning manufacturers produce cubing systems with similar capabilities, you might be surprised to learn that they can differ significantly in cost. In general, pallet dimensioners using laser-based technologies are far more expensive than dimensioners using infrared technologies. The difference in price can be tens of thousands of dollars per unit.

Also consider the eventual scalability of your dimensioning operation. Will you ever need install multiple dimensioning systems to expand your pallet throughput? Would you like to install cubing systems at multiple facilities? When purchasing or planning to purchase multiple units, the price of a pallet dimensioner becomes an even more critical consideration.