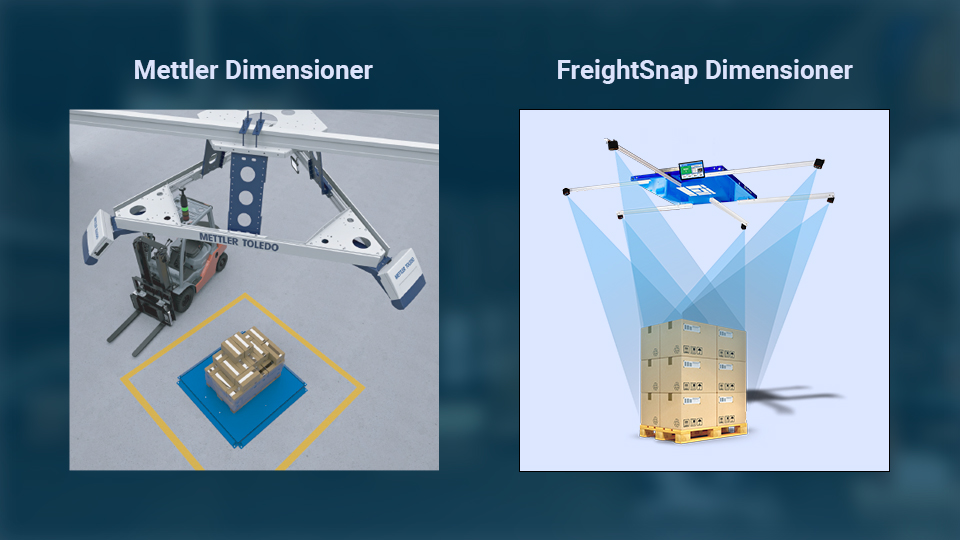

It is no secret that Infrared technology is different today than it was 10 years ago. Recently, one of the Dimensioner Manufacturers, who utilizes Lidar technology threw out some old and debunked views about the differences between Lidar and Infrared technology. I felt compelled to set the record straight once and for all. First of all, I have no ill will toward Lidar technologies and when contrasting Dimensioning units with the different technologies, I always state my opinion that I feel the Lidar products are very good. They are just really expensive for the stated purpose of what we are trying to do. That is measure palletized freight. First of all, let’s clear the air. All of the units are tested to be used in a “Legal For Trade” scenario. Secondly, they are tested with all kinds of colors and materials so as to make sure that these devices can be trusted in a wide array of environments and applications. The entire purpose of testing is to give the user the confidence that they can trust the results. So when a Lidar company comes out and says they do it better, that is disingenuous at best, and misleading at worst.

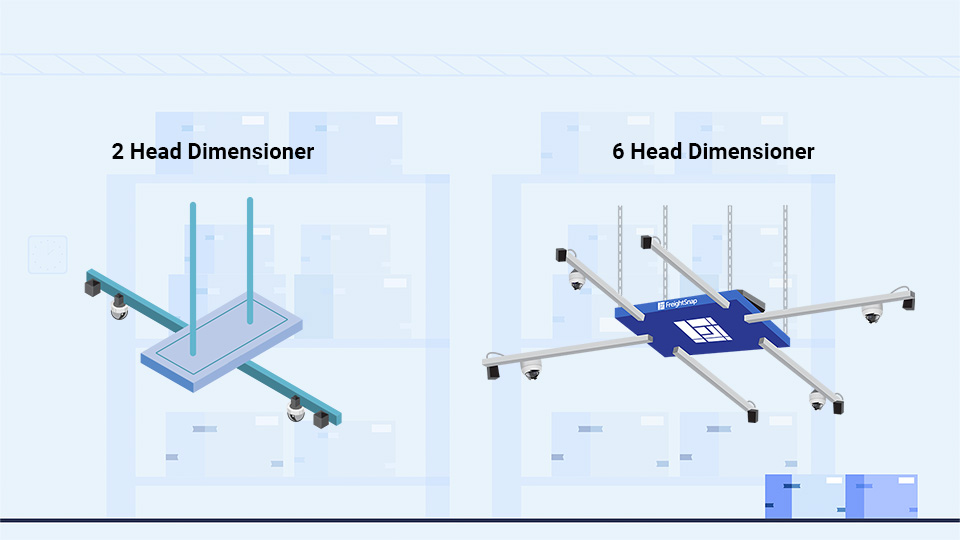

As far as technological differences, it is pretty straight forward. Lidar is a 2D product which needs to be rotated to create a 3D data which can be utilized to produce a 3D image capable of producing a pallet measurement. An Infrared sensor is capable of producing a 3D dataset without being manipulated by movement or reflection. Lidar is great for determining the distance measurement down to a millimeter when not being manipulated. Take for instance when the policeman points the laser at an oncoming car. The measurement is usually pretty good and that is because it is not manipulated. Infrared is very good at detecting the distance down to a Centimeter or 1/4 inch without manipulation. The issue for Lidar is while the unmanipulated data is solid, when you have to reflect light with a mirror or move the light with a rolling structure, you are limited to the accuracy of the encoding mechanism, which in most cases, is less accurate than the capability of the lidar itself. This is where the confusion sets in. 3D’s accuracy in a static position never changes. Lidar sensors that require secondary devices to move the lasers or reflect them, are at the mercy of the equipment gauging the movement. When you take that into consideration, both devices yield very similar results even though one technology, Lidar, is capable of greater accuracy. For pallet measurement, both yield similar results, and you can’t dispute the NTEP Certification and testing that has been done to prove this. Manufacturers will claim a Lidar device is capable of 1 Millimeter accuracy, and they would be right, but their encoder is only capable of 1 Centimeter accuracy, and because of that, the level of accuracy achieved in 3D modeling is still 1 Centimeter. The best analogy I can provide is that of a large engine and a carburetor. The engine might be capable of faster speeds, but the carburetor can only feed fuel in at a rate to achieve a lesser speed. In this analogy, the carburetor is the encoder. Right now, they don’t produce encoders capable of the same accuracy as a Lidar sensor when producing a 3D model. The good news is the LTL industry is perfectly fine with 1/2 to 1″ accuracy in measurement. Both Lidar and Infrared sensors are more than capable of that precision.

With regards to accuracy, it depends upon your application. If you are trying to measure a pallet to within ½” then either technology provides you with the accuracy level to achieve your goal.

Cost wise, there is a huge difference. And this is where the Lidar vendors start to grit their teeth. Lidar devices are on a cost magnitude 4 times as expensive as an infrared sensor and they also require expensive moving chassis and calibration to make them work. Infrared devices can work from a fixed position and thus are much less expensive to calibrate and mount. When someone says you get what you pay for, then in this case that is right. You either get cost effective infrared to measure within ½” or very expensive Lidar to measure within ½”. So when you pay more for Lidar, that is what you get, Lidar.

In the article about the two technologies, it was mentioned that Infrared has trouble with Black or other colors. This is old news and a talking point that goes back to ten years ago. It is true that some of the original Infrared sensors were created to run on lower frequencies and did indeed have trouble with some colors. Over time, as with any emerging technology, the manufacturers address short comings and create better products. Today’s Infrared sensors are faster, run at higher frequencies, and have no issues with colors of any kind.

Someone once asked me why some manufacturers utilize Lidar when it puts them at such a cost disadvantage? My answer is pretty simple. They had a 4-year Head start and made the decision to use Lidar because Infrared wasn’t available at the time. Once you head down a road, it is hard to take a step in a different direction. Especially if you have sales people bad mouthing the other technology. That being said, many Lidar based manufacturers are racing to come up with Infrared solutions.

In summary, advances in technology help bring efficiency to businesses and promote productivity. That being said, there is an ROI when adopting new technologies, and today’s companies are more in tune with that way of thinking. They no longer are taking the conservative approach and just throwing money at solutions. They are more open minded to new thinking, to newer technologies, and most of all, to spending wisely. The technology must match the application. Using Lidar for pallet measurement is like bringing a sledge hammer to pound a nail. It will get it done quite effectively, but an actual hammer will do, and the hammer is much less expensive.